UGW is an experienced braided hydraulic hose manufacturer, producing, supplying, exporting, braided hydraulic hoses conforming to 1SN, 2SN, 2SC, 2SNK, R16, R17 for global customers.

Braid hydraulic hose are produced by advance USA Magnatch machine, this machine is famous of 2 wire- braiding, make sure rubber material and steel wire are well combined to make sold construction.

UGW strictly control each steps in braid hose manufacturer, the overall quality of hose is able to meet or exceed SAE/EN/DIN standard. With developing technology hose overall working performance, UGW braided hydraulic hose quality meet superior flexibility, tigher bend radius and excellent resistance of kinking performance. Widely apply to hydraulic system, mobile machinery for various industrial service, and other applications.

If you are looking for bulk hose, or custom braid hose assembly, UGW are able to provide you customized cut length, OEM private brand layline braided hydraulic hose with superior quality & fast lead time.

Types of Braided Hydraulic Hose

1SN Braided Hydraulic Hose

✔ Standard:DIN,EN 853、 SAE 100 R1AT, MSHA approval

✔ Reinforcement:1 high tensile steel wire braid

✔ Application:low to medium pressure Hydraulic System

2SN Braided Hydraulic Hose

✔ Standard: DIN, EN853、SAE100 R2AT, MSHA approval

✔ Reinforcement:2 high tensile steel braids

✔ Application:Medium to high pressure Hydraulic oil lines

2SC Braid Hydraulic Hose

✔ Standard: DIN, EN857,exceed SAE100 R2 and R16

✔ Feature: Compact size, and better flexibility

✔ Application: High pressure service with tighter bend radius

2SNK Braided Hydraulic Hose

✔ Standard:Exceed DIN EN 857 2SC and SAE 100 R16 standard

✔ Feature: Excellent impulse performance, higher working pressure at reduced bend radius.

✔ Application: high pressure hydraulic application require better flexibility

R16 Braided Hydraulic Hose

✔ Standard: SAE100 R16

✔ Reinforcement:2 high tensile steel braids

✔ Application: Compact hose for Agriculture, building & construction, mining, material handling, hydraulic system application

R17 Braided Hydraulic Hose

✔ Standard:SAE100 R17

✔ Reinforcement:1 or 2 high tensile steel wire braids

✔ Feature: Isobaric hose with constant working pressure 21 Mpa.

✔ Application: Medium presssure hydraulic application which require more flexibility.

Advantages of Braided Hydraulic Hose

Braided hydraulic hose is made of synthetic rubber and 1 or 2 wire steel wire reinforcement. Because of the steel wire layer, wire braid hose is flexible, the reduce bend radius show more flexibility when handle and install assembly on machinery.

✔ Provides superior oil resistance, heat resistance and aging resistance by using special synthetic rubber

✔ Provides high pressure resistance and superior impulse resistance

✔ Provides superior bonding in hose internal, soft use and small deformation under pressure

✔ Provides superior kink resistance and fatigue resistance5. Provides longer service life

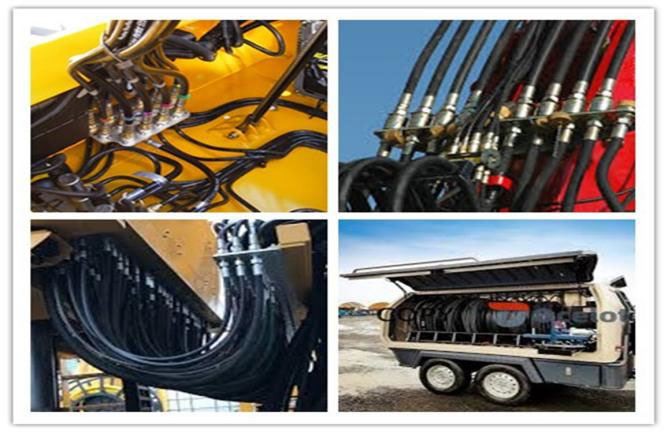

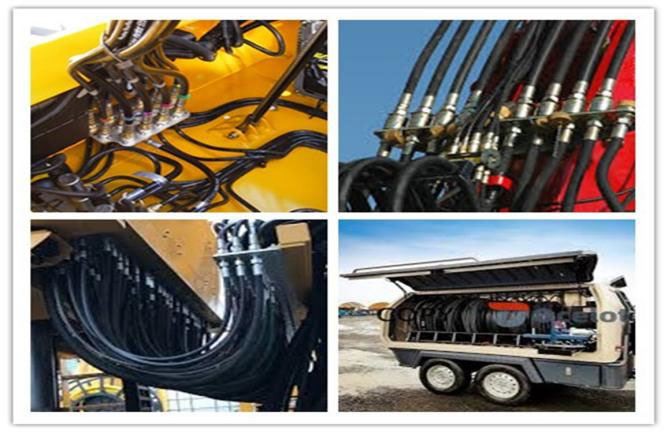

Braided Hydraulic Hose Applications

Braid hydraulic hose is mainly serve for mining, oil field, engineering construction, agricultural machinery, lifting and transportation machinery, injection molding machinery, and some other machine tool and automatic hydraulic system, which need to transfer hydraulic fluid for motivation under certain pressure and temperature requirement.

high and medium pressure petroleum, water-based, and general industrial fluid conveyance.

Why Choose UGW as Braided Hydraulic Tube Supplier

For over two decades years, UGW is specialized in designs, manufacturing and distribution of braid hydraulic hose. We located in Hebei, China. Developing into 70,000m³ plant scale for 3 factories. Every plant is assembly with advanced machines for manufacture and quality inspection, such as USA Magnatech Braider and Italy Bimal Test machine. Our annual capacity is keep improving to meet increasing need and fast lead time, by 2024, annual capacity is around 30 million meters.

In addition to international SAE/EN/DIN standard, UGW have own development of braided hose product which with exceptional working performance, hose can be ued for pressure up to 450Bar, and impulse cycles which is up to 750,000 for high-requirement hydraulic applications.

UGW one or two wire braid hydraulic hose shows flexibility at a tighter bend radius, with small deformation under pressure, and good resistance to kinking and fatigue. Before delivery mass production to our customer, plant would do a complete of quality inspection, for general parameters check to burst test, impulse test, abrasion, ozone test, leak test, Low temperature bending test, etc.

The braid hydraulic hose are qualified by MSHA, API, MA, CCS. ISO9001-14001-18001, RoHs & REACH. Ideal for high and medium pressure petroleum, water-based, and general industrial fluid conveyance.

UGW supply a complete range of braid hydraulic hose and fitting, adapter product with compact size from 1/4’’ - 3’’. Besides, we provide custom cut length hose and pre-assembly with your private brand labeling service.

In response to hose or fitting product which are beyond the standardized parameter, we can confirm with plant engineers and update the details accordingly.

UGW braided hydraulic hose Minimum Order Quantity is 600meter per size. For some big size, MOQ is negotiable. For first trail order, we support to start from small quantity. Should you have any request, please check with our sales team.

UGW understand quality confirmation is key factors for both sides cooperation, and we would like to provide sample to client for regular checking or testing. Should you have request on sample, please check more details with our sales team.

Sourcing Braided Hydraulic Tubing from UGW to Boost Your Business

✔ For Brand Owners

Able to apply certain hose parameter, and produce hose following brand quality level. Be reliable on fast lead time and quality standard, help private brand be with more good reputation and more market share . Support with updated technology and market information.

✔ For Traders

Quick response on your demand, Highly coordinated efficiency and support your needs with professional product knowledge and market background.

✔ For Construction Machinery Manufacturers

Provide OEM service according to your machinery requirement. Supported by professional engineers and sales teams to produce the superior quality level braid hydraulic hose, fitting and custom hose assembly product that meet your machinery applications.

Braided Hydraulic Hoses: The Helpful Guide for Importers

What is Braided Hydraulic Hose?

It is mainly composed of liquid-resistant synthetic rubber inner rubber layer, middle rubber layer, Ⅰ, Ⅱ and Ⅲ layers of steel wire braided layer, and weather-resistant synthetic rubber outer rubber layer. The outer rubber layer protects the steel wire from damage, and the steel wire layer is the skeleton material and plays a reinforcing role.

What Are the Different Types of Braided Hydraulic Hose?

1 wire braid: 1SN, 1SC, 1ST, R17(1/4”, 3/8”, 1/2”)

2 wire braid: 2SN, 2SC, 2ST, R16

What is Braided Hydraulic Hose Structure?

Steel wire braided hydraulic hose is made of one or two high tensile steel wires reinforcement and composed of an inner rubber layer and outer rubber layer. Rubber material is with superior abrasion resistance ability.

Where Are Braided Hydraulic Hoses Used?

Steel wire reinforced hydraulic rubber hose is mainly used for mine hydraulic support, oil field mining, suitable for engineering construction, lifting and transportation, metallurgical forging, mining equipment, ships, injection molding machinery, agricultural machinery, various machine tools and mechanization and automatic hydraulic pressure in various industrial sectors Transporting petroleum-based (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricating oil) liquid, water-based liquid (such as emulsion, oil-water emulsion, water), gas, etc. and liquid transmission with certain pressure and temperature in the system use.

What Are the Advantages of Braided Hydraulic Hoses?

1. The hose is made of special synthetic rubber, which has excellent oil resistance, heat resistance and aging resistance.

2. The hose has high bearing pressure and excellent pulse performance.

3. The tube body is tightly combined, soft to use, and less deformed under pressure.

4. The hose has excellent bending resistance and fatigue resistance.

5. The length of the steel wire braided hose is large, the fixed length above φ32 is 20 meters, and the length below φ25 can reach ten meters or even more than 100 meters.

Applicable temperature: oil -40°C-+100°C, air -30°C-+50°C, water emulsion below +80°C, please choose our special products if it exceeds.

How to Produce the Braid Hydraulic Hose?

Step 1: Extrude inner rubber – The inner rubber are extruded on the hose mandrels..

Step 2: Air drying – Get the hose clean and dry.

Step 3: Reinforcement with steel wire layer – Braid the steel wire layers reinforcement with our Magnatech braiding machines.

Step 4: Extrude outer rubber and print label – Extrude the outer rubber with abrasion and flame resistant, print our layline or the customized layline on the hose.

Step 5: Wrap water cloth – Wrap the water cloth on the hose to protect it in the vulcanization process.

Step 6: Vulcanize – Direct steam heating of vulcanizing boiler or continuous vulcanizing.

Step 7: Remove water cloth –Remove the water cloth from the hose after vulcanization.

Step 8: Proof test - Proof test with 2 times of max working pressure.

Step 9: Quality Test – Impulse test and bursting test on the test platforms.

Step 10: Measurement and Packaging – Measure the length of rubber hoses and get the hose packed with our standard way.

Tips when You Install the Braided Hydraulic Hose?

Avoid distorting the assembly when installing. When installing the hose assembly, work with the right way to avoid distorting the assembly.

Avoid exceeding the minimum bend radius when installing. Please choose the proper fitting type to make sure the hose will not exceed the minimum bend radius.

Avoid the hose is installed with contacting objects. Please choose the proper hose length in case of abrasion or damage.

How Long is the Service Life of the Braided Hydraulic Hose?

Hydraulic hose working life is affected by many factors, for example, working pressure, working temperature, installation bend radius, hydraulic fluids. If hose is working to application which is very tough, and beyond hose parameters, valid service life would be much less and easy to broke. While hose is install at right place, the service life could be up to Max 5 years or more. UGW hose is made with solid construction of abrasion resistance cover and high tensile steel wire, you can be well sure the quality to long and safe service time.

What Are the Standards for Braided Hydraulic Hose?

SAE Standard: This SAE Standard provides general, dimensional, and performance specifications for the most common hoses used in hydraulic systems on mobile and stationary equipment.

EN Standard: EN is the abbreviation of European Standards, also as DIN EN standard, and hydraulic hose EN standard will be printed on the surface of the hydraulic hose outer cover.

ISO 18752 standard: ISO 18752:2014 specifies requirements for ten classes, four grades and seven types of wire- or textile-reinforced hydraulic hoses and hose assemblies of nominal sizes ranging from 5 to 102. Each class has a single maximum working pressure for all sizes. Such hoses are suitable for use with hydraulic fluids HH, HL, HM, HR and HV as defined in ISO 6743-4 at temperatures ranging from -40 °C to +100 °C for types AS, AC, BS and BC and -40 °C to +120 °C for types CS, CC and DC.

How to Choose a Braid Hydraulic Hose Supplier?

Choose a supplier that has standard production process, standard quality control process.

Choose a supplier that is equipped with the skills and knowledge to offer the best customer service.

Choose a supplier with lots of experience will have a team of qualified, experienced and highly-trained hydraulics engineers who have been specially trained in their field.

Choose a supplier that not only supplies hydraulic hoses, but also offers after services and support, too.

What is the Disadvantage of Braided Hydraulic Hose?

As we know, compared with spiral hydraulic hose, wire braid hydraulic hose more flexible and tighter minimum bend radius. That means braid hydraulic hose is easy to handle and assembly than spiral hydraulic hose. Meanwhile, because of this advantage comes one main disadvantage–braid hydraulic hose working pressure has limit, it does not suit high pressure and performance not well than spiral hydraulic hose in high-impulse applications.

For example, under high-impulse applications, when a hose is pressurized, wire braid hydraulic hose is more susceptible to failure than wire spiral hydraulic hose. When you choose hydraulic hose, you should according to your applications do a better choice.

High-impulse applications are better served by wire spiral hydraulic hose, not wire braid hydraulic hose.

What Are the Specifications of Braided Hydraulic Hoses?

According to the layer, wire braid hydraulic hoses can be mainly divided into two types which are widely used in the markets. They are namely single wire braid hose and double wire braid hose.

Single wire braid hose construction: the inner tube is oil resistant synthetic rubber and one braid of high-tensile steel wire reinforcement with oil resistant, environment resistant synthetic rubber. Main application: medium pressure hydraulic application including mobile, machine tool, and agricultural application, using petroleum or water based hydraulic fluids. It can withstand temperature of -40°C to +100°C(-40°F to 212°F), and the maximum temperature can be +125°C. Main types: DIN EN857 1SC , SAE 100R17 (from 1/4''size to 1/2'' size) , SAE 100R1A/DIN EN853 1ST , SAE 100R1AT/ DIN EN853 1SN , SAE 100R2A / DIN EN853 2ST , SAE 100R5.

Double wire braid hose construction: the inner tube is oil resistant synthetic rubber and two braids of high-tensile steel wire reinforcement with oil resistant, environment resistant synthetic rubber. Main application: high pressure hydraulic oil lines used in construction, machine tool, and agriculture application using petroleum or water based hydraulic fluids. It can withstand temperature of -40°C to +100°C(-40°F to 212°F), and the maximum temperature can be +125°C. Main types: DIN EN857 2SC , SAE 100R16 , SAE 100R2AT / DIN EN853 2SN, SAE 100R17 (from 5/8''size to 1'' size)

Why Do Need Braided Hydraulic Hoses?

First of all, you need to understand clearly what steel wire braided hydraulic hose is, and then you can better understand why you need steel wire braided hose.

All steel wire braided hose have the same three layers: inner tube determines what type of fluid can be conveyed, a reinforcement layer and an outer tube. And as the name suggests, this layer consists of alternating cross-patterned steel wires, forming a braid. The manufacturing process is quite complicated and requires huge braiding machinery to form braids on the extruded inner tube. It is precisely because of the interlocking pattern of the braids that they have higher tensile strength, more flexibility, and smaller The bend radius is ideal for installation in applications where space is limited and requires twisting to install.

What's more, for medium and low pressure applications of 3,000psi or less, it need braid hydraulic hose. For example, medium and low pressure applications in oilfield mining, engineering construction, lifting and transportation, metallurgy, forging, mining equipment, ships, injection molding machinery, agricultural machinery and various machining tools.

How Does the Braided Hydraulic Hose Transmit Hydraulic Pressure?

Hydraulic hoses generally use hydraulic oil to transmit force (in this case system pressure) to perform specific actions. Carry out hydraulic power transmission or transport high-pressure media such as water, gas, oil, etc., to ensure the circulation of liquids and transfer liquid energy.

The steel wire braided hydraulic hose is mainly composed of liquid-resistant inner rubber layer, middle rubber layer, 1 or 2 layers of steel wire braided reinforcement layer, and outer rubber layer. The inner rubber layer has the function of making the conveying medium bear the pressure and protecting the steel wire from erosion. , The outer rubber layer protects the steel wire from damage, and the steel wire layer is the skeleton material for reinforcement and reinforcement. Different layers will affect the hydraulic pressure and endurance.

Will the Braided Hydraulic Hose Burst?

If the hydraulic hose is selected and used normally, the hose will not burst under normal circumstances. If there is a problem with the selection, installation, using, the hose will occur burst situation.

As we know, Different types and sizes of hoses will have a reference to the maximum working pressure and maximum burst pressure, their ratio named safety factor. If you select unsuitable pressure hydraulic hose, the working pressure exceeds the maximum burst pressure, a burst will occur.

Secondly, whether you select the correct hose fitting or install hose fitting according to correct crimp data. If the operation not correct, assembly will also burst during testing or use.

In addition, when the braid along the outside of the hose will be visibly broken. Furthermore, there will be minimized outward deflection of wire in the relative area. When this occurs, it is clear that the hose can no longer work effectively, after burst happens, you should assess the application and then replace the entire hose assembly, otherwise, burst again.

How Do I Know if Braided Hydraulic Hose is High or Low Pressure Hose?

Steel wire braided hydraulic hose have 2 kinds of steel wire reinforcement layer. One is 1-layer steel wire braided and the other is 2-layer steel wire braided hose. Generally, steel wire braided hose suitable for low to medium pressure hydraulic fluid applications, and show superior flexibility.

Compare the same size with different steel wire layer, 2 layers of steel wire reinforcement working pressure is higher than 1 steel wire layer. And if we compare different model in same layer of steel wire, 2SC hose might have higher working pressure and with better flexibility than 2SN. Each model have it parameters and able to meet a variety of requirements. Besides, there is also a constant pressure steel wire braided hose, such as R17, part of size is made of 1 steel wire and bigger size from 5/8’’ is made of 2 steel wire layer, but all hose remain at same middle working pressure 21 Mpa.

What is Working Pressure Range Can Braided Hydraulic Hose Withstand?

The steel wire braided hose is composed of rubber, high strength steel wire reinforcement. Each part is tightly combined to withstand low pressure to high pressure, for example 40 Bar - 415 Bar (580psi-6000psi). Each model and each size refer to different max working pressure range. It is suitable for various construction machinery, construction projects, etc., to transport hydraulic fluid.

What is the Difference Between Braided Hydraulic Hose and Spiral Hydraulic Hose?

The biggest difference is on the manufacturing technic on steel wire reinformance, one is braiding, showing criss-cross on the hose cutting appearance, with 1 or 2 layer steel wire reinforcement. The another is spiral steel wire, showing tidy 4 or 6 layers steel wire reinforcement on hose cutting appearance. The different on steel wire layer, also mean the difference of working pressure, spiral hose working pressure is higher to Max 2400 Psi - 6500 Psi.

The second different is on inner and outer cover diameter, spiral hydraulic hose is thick, bigger, heavier than braid hose, which also show only a little advantage on flexibility.

Braid hydraulic hose and spiral hydraulic hose are different kinds of hydraulic hose rubber hose, they apply to different application with their own advantage and disadvantage.

What is the Difference Between Single-layer and Double-layer Braided Hydraulic Hose?

Due to the change of the number of steel wire layers, the parameters of the hose pipe change, such as the thickness of the steel wire, the inner rubber and outer thickness and diameter of hose will increase accordingly. And all the parameter, affect the working pressure and bend radius - flexibility.

1 wire braided hydraulic hose apply to low - middle pressure hydraulic applications including agricultural, mobile machinery tool with petroleum or water based hydraulic fluid, while double layer braided hydraulic hose is apply to middle - higher working pressure, able to meet a wide variety of hydraulic applications.

Can We Replace Braided Hydraulic Hose with Fiber Braided Hydraulic Hose?

As braided hydraulic hose and fiber braided hydraulic hose is made with totally different reinforcement material, we cannot replace one with the another. The difference of reinforcement material (one is a fiber layer, one is a steel wire braid) is the key factors of hose performance and determining the working application.

Fiber braided hydraulic hose only withstand with low working pressure, and steel wire braided hydraulic hose are suitable for applications and industries that require higher performance in working pressure and transfer variety kinds of hydraulic fluid.

What is the Working Temperature Range of the Braided Hydraulic Hose?

Oils -55℃ to +150℃ Air-30℃ to +50℃ Water Emulsion Under +80℃

Why is It Important to Choose the Best Braided Hydraulic Hose?

The best braid hydraulic hose can help you get the maximum life expectancy, and the braid hydraulic hose selected will last for many years, so quality is the most important, you need to pay more attention to the selection of hydraulic hose before the project.

High-quality braid hydraulic hoses can provide the best value for your business and keep your construction or construction projects running smoothly.

Good braid hydraulic hoses can save a lot of time and money on ongoing maintenance, and you won't have to pay extra to replace them often.

The most important thing is safety, you must carefully choose hydraulic hoses that can withstand the working pressure.

What is the Specification Range of the Braided Hydraulic Hose?

Braided hydraulic hose is available in inside diameters of ¼” to 2,” depending on grade.

How Many Layers of Steel Wire Are There in the Braided Hydraulic Hose?

1 and 2 floors. The more layers, the higher the pressure.

Hazards of Braided Hydraulic Hose Failure?

Spiral hydraulic hoses have a limited lifespan and can be shortened by a number of factors. Hydraulic press hoses often receive little or no attention until they fail. Hydraulic hose failures cost more than replacing hoses. Additional fees may include:

– Clean, dispose of and replace lost hydraulic oil.

– Accidental damage to other components, such as a hydrostatic driven hose failure, may result in a loss of charge pressure and cavitation damage to the drive pump and/or motor.

– Possible damage caused by the entry of contaminants.

– Machine downtime.

What is the minimum order quantity for UGW braided hydraulic hose?

The minimum order quantity of UGW wire braided hydraulic hose is 600 meter per size. For some large sizes from 1” to 2” , the minimum order quantity is negotiable.

Can I get free samples braided hydraulic hose from UGW?

Yes, we are willing to provide customers with free samples for checking product quality.

What customized hose service does UGW provide?

Whether it is hydraulic hoses, fittings or other accessories, UGW can provide customized services. For hose production, we can produce tubes with your brand logo, custom hose layline information. For joint part (fitting, quick coupler, adapter), production can be customized & produce according to drawings or real samples, and also print your brand name and trademark. We also provide professional pre assembly hose as required. Whatever you need, please check with our sale consultants, they would provide fast and effective service and suggestion.

Which certifications does UGW Braided Hydraulic Hose are compliant?

Each of UGW hydraulic hose is produce following EN/SAE/DIN standard, and in compliance with stringent industry level, such as MSHA, API, ISO and CE, suitable for applications in construction machinery, mining rulings, transport machinery, marine equipment and oil exploration, and delivery high performance, withstand the harshest working environment. Hose product also comply with critical RoHs and REACH - a European community regulation, hose material show very limit component of harmful chemical substances, we aim to protect user's health and make effort for earth clean as a professional and responsible entrepreneur.

Is UGW a hose supplier or trader of braided hydraulic hose?

UGW (company name Youlu Shanglai Fluid Technology) is a professional manufacturer of wire braided and spiral hydraulic hoses. We produce, we supply, and we export to hydraulic distributors around the world, as well hydraulic machinery companies, construction machinery and some other terminal users who need hydraulic hoses. Now, we have established cooperative relationships with more than 30 brands, mainly in North America, Europe and Southeast Asia market, providing high-quality, advantageous and fast-delivery hose & fitting products.

What standards does UGW braided hydraulic pipe implement?

UGW steel wire braided hydraulic hoses meet SAE EN DIN and some international certifications, such as MSHA, api, rohs and reach. The production of UGW has a mature set of processes from raw material purchasing to final inspection. We use good quality quality and advance machine, with plant staff’s effort and parameter control of each step in production, UGW hydraulic hose is performancing good quality at work, and obtained good reputation in the market. Till today, we never ending improving technic to meet higher hydraulic application requirements.

What is the lead time of UGW braided hydraulic hose?

Lead time is affected by the final quantity. Roughly estimated for a 20’ full container, which can load around 33m³, the delivery time is about 30-40 days. And for a 40 large full container in 50-60 days. The joint and customized assembly order need to be discussed according to actual needs.

UGW third factory will be put into operation in early 2023, by then, annually hose production capacity forecast to increase to 30 million meter per year, we aim to improve work efficiency and provide customers with stable and fast delivery and quality-assured products.